In the realm of modern precision machining, the demand for high - quality, efficient, and reliable equipment has never been greater. The precision machining industry is constantly facing challenges such as tight tolerances, complex geometries, and the need for rapid production cycles. To address these challenges, the copper electrode CNC engraving and milling machine DC6050A emerges as a game - changer.

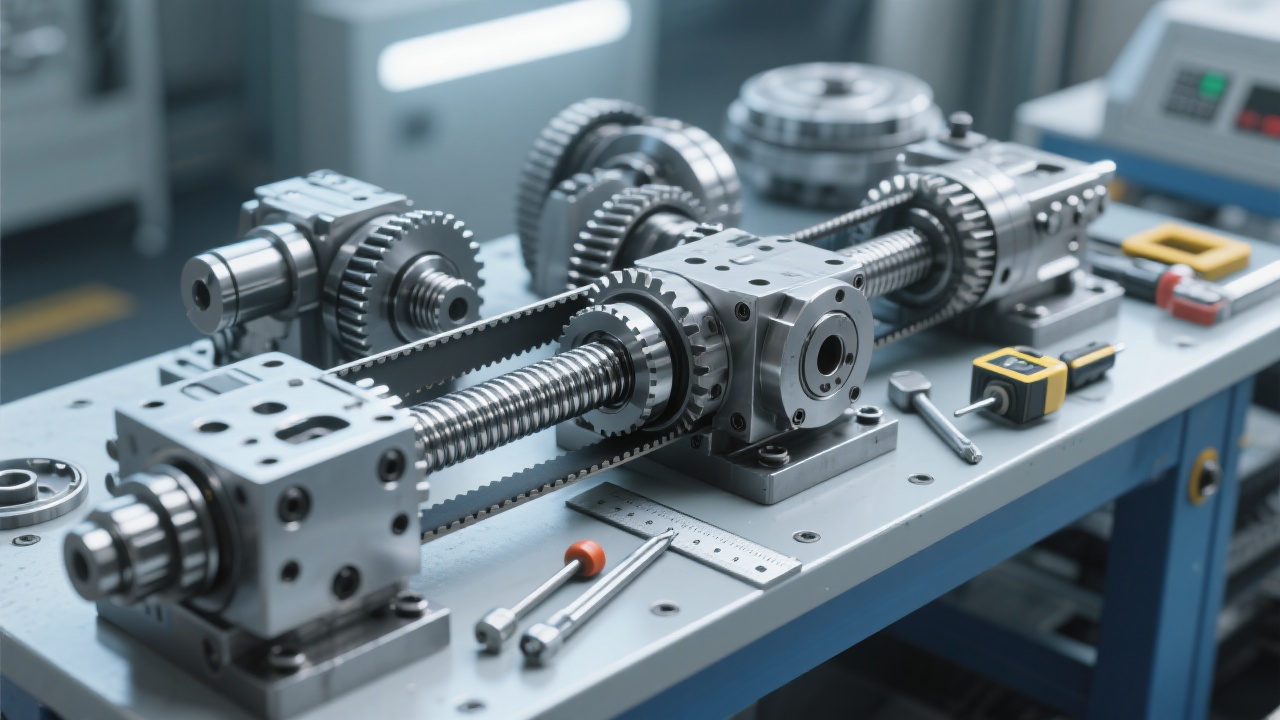

The DC6050A is specifically designed for precision engraving and milling operations. It is equipped with advanced control systems that ensure high - speed and high - precision movement. For example, its spindle speed can reach up to 24,000 RPM, which allows for efficient material removal while maintaining excellent surface finish. The positioning accuracy of the machine is within ±0.005mm, and the repeat positioning accuracy is within ±0.003mm.

These technical parameters are far superior to many of its competitors in the market, making it an ideal choice for high - end precision machining tasks.

In the field of precision aluminum mold processing, the DC6050A shows remarkable performance. Aluminum molds often require high - precision surface finishing and complex cavity machining. The machine's high - speed spindle and precise control system can handle these requirements with ease. In a case study of a mold manufacturing company, the use of DC6050A reduced the processing time of an aluminum mold by 30% compared to the previous equipment. At the same time, the surface roughness of the mold was reduced from Ra 0.8μm to Ra 0.4μm, significantly improving the quality of the mold.

When it comes to general metal product processing, the DC6050A also shines. It can process a variety of metals, including steel, copper, and titanium. The machine's powerful cutting ability and stable performance ensure consistent quality in mass production. For instance, in a metal parts manufacturing factory, the production efficiency of small - sized metal parts increased by 40% after adopting the DC6050A, and the reject rate was reduced from 5% to 1%.

Precision steel engraving requires high - precision control and fine cutting ability. The DC6050A can achieve engraving depths of up to 2mm with a line width accuracy of ±0.01mm. In a steel engraving project for a high - end jewelry brand, the machine was able to create intricate patterns with excellent clarity and precision, which was highly praised by the client.

Potential customers in the precision machining industry have high expectations for processing accuracy and production cycles. The DC6050A can precisely meet these needs. Its high - precision control system ensures that the products meet the strictest tolerance requirements. And its high - speed processing ability shortens the production cycle, enabling customers to quickly respond to market demands.

In a survey of customers who have used the DC6050A, 90% of them said that the machine has effectively improved their production efficiency and product quality.

The copper electrode CNC engraving and milling machine DC6050A is a powerful and reliable solution for the precision machining industry. With its outstanding technical features, excellent performance in various applications, and the ability to meet customer needs, it is undoubtedly the ideal choice for businesses looking to enhance their competitiveness. If you are in the market for a high - quality precision machining equipment, don't miss the opportunity to experience the DC6050A. Click here to learn more about the DC6050A and how it can transform your precision machining operations!

We encourage you to share your specific needs or ask any questions you may have in the comments section below. Let's start a conversation about how the DC6050A can be the key to your business success.

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home