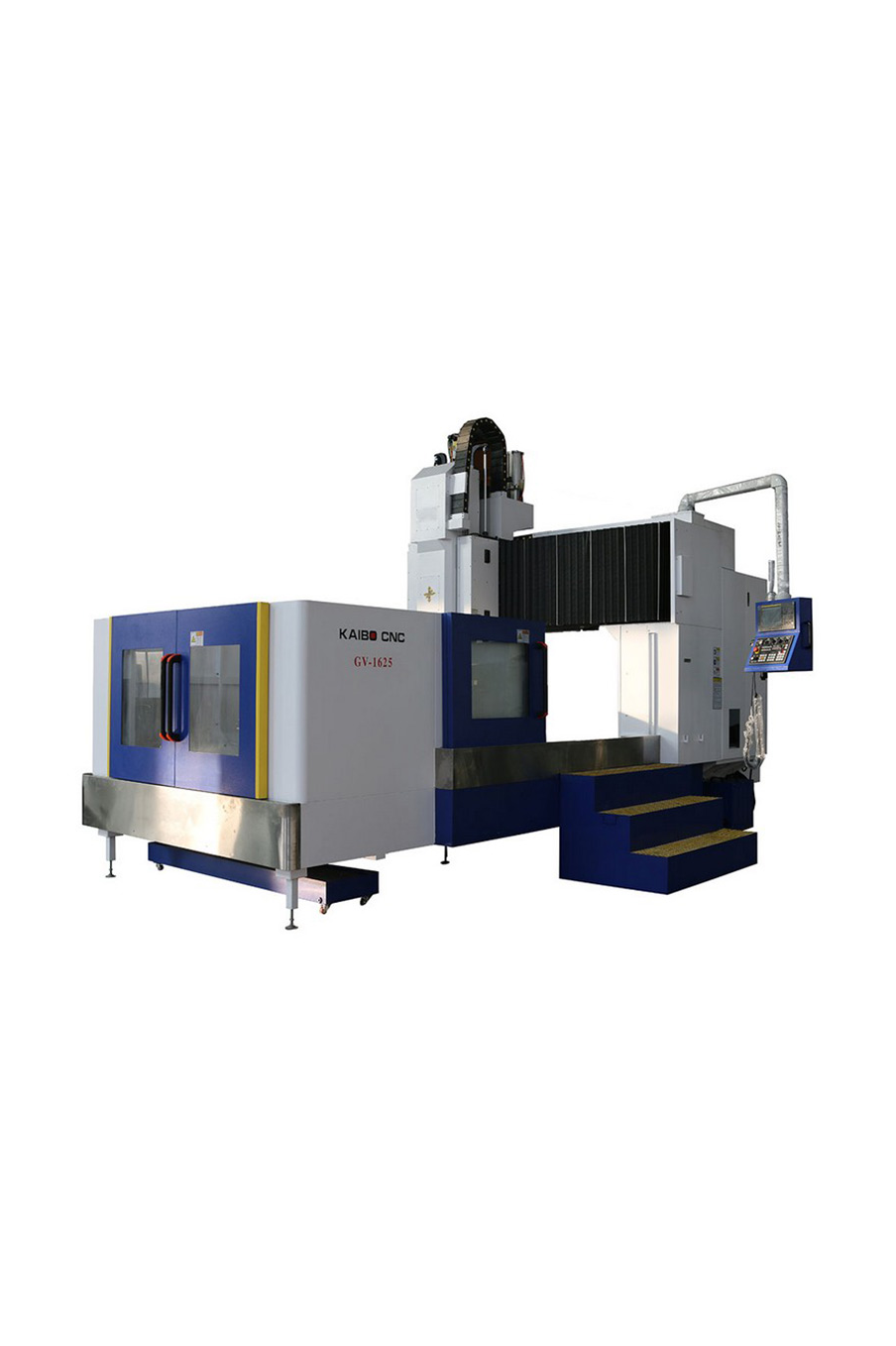

The DC2025龙门数控铣床 is a high-performance double-column vertical machining center designed specifically for large mold manufacturing. With its exceptional rigidity and precision, it has become the preferred choice for industries that demand accuracy, efficiency, and reliability in complex machining operations.

One of the key features of the DC2025 is its ability to maintain high precision even during long and continuous machining processes. The machine is equipped with advanced linear guides and high-precision ball screws, ensuring minimal deviation and consistent performance. According to internal testing data, the DC2025 achieves a positioning accuracy of ±0.02 mm and a repeatability of ±0.01 mm, which is significantly better than industry averages.

For example, a leading automotive parts manufacturer in Germany reported a 30% reduction in rework after switching to the DC2025. The improved precision not only reduced material waste but also enhanced the overall quality of their molds, allowing them to meet strict international standards.

The double-column structure of the DC2025 provides excellent rigidity, making it ideal for heavy-duty machining tasks. This design minimizes vibration and deformation, which are common issues in large mold production. The machine’s robust frame and optimized support system ensure stable cutting conditions, even when working with large workpieces.

In a recent case study, a mold manufacturer in China used the DC2025 to produce a 4-meter-long mold for a consumer electronics product. The machine completed the job in half the time compared to their previous equipment, while maintaining the required dimensional accuracy throughout the process.

By combining high precision with strong rigidity, the DC2025 helps manufacturers reduce cycle times and increase productivity. Its powerful spindle, capable of reaching up to 6,000 RPM, allows for efficient material removal without compromising surface finish or tool life. Additionally, the machine supports multiple tool changes and automated loading, further streamlining the production workflow.

A comparison between the DC2025 and a conventional machining center showed that the DC2025 can complete large mold projects up to 40% faster. This efficiency translates into lower operational costs and higher profit margins for businesses.

The DC2025龙门数控铣床 is more than just a machine—it's a strategic investment in quality and competitiveness. With its proven track record in large mold manufacturing, it offers:

For manufacturers looking to elevate their production capabilities, the DC2025 is the ultimate solution. It not only meets current demands but also prepares your business for future challenges in the evolving manufacturing landscape.

Ready to take your mold manufacturing to the next level? Request a free quote today and experience the power of precision with DC2025.

Get Your Free Quote NowThe page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home