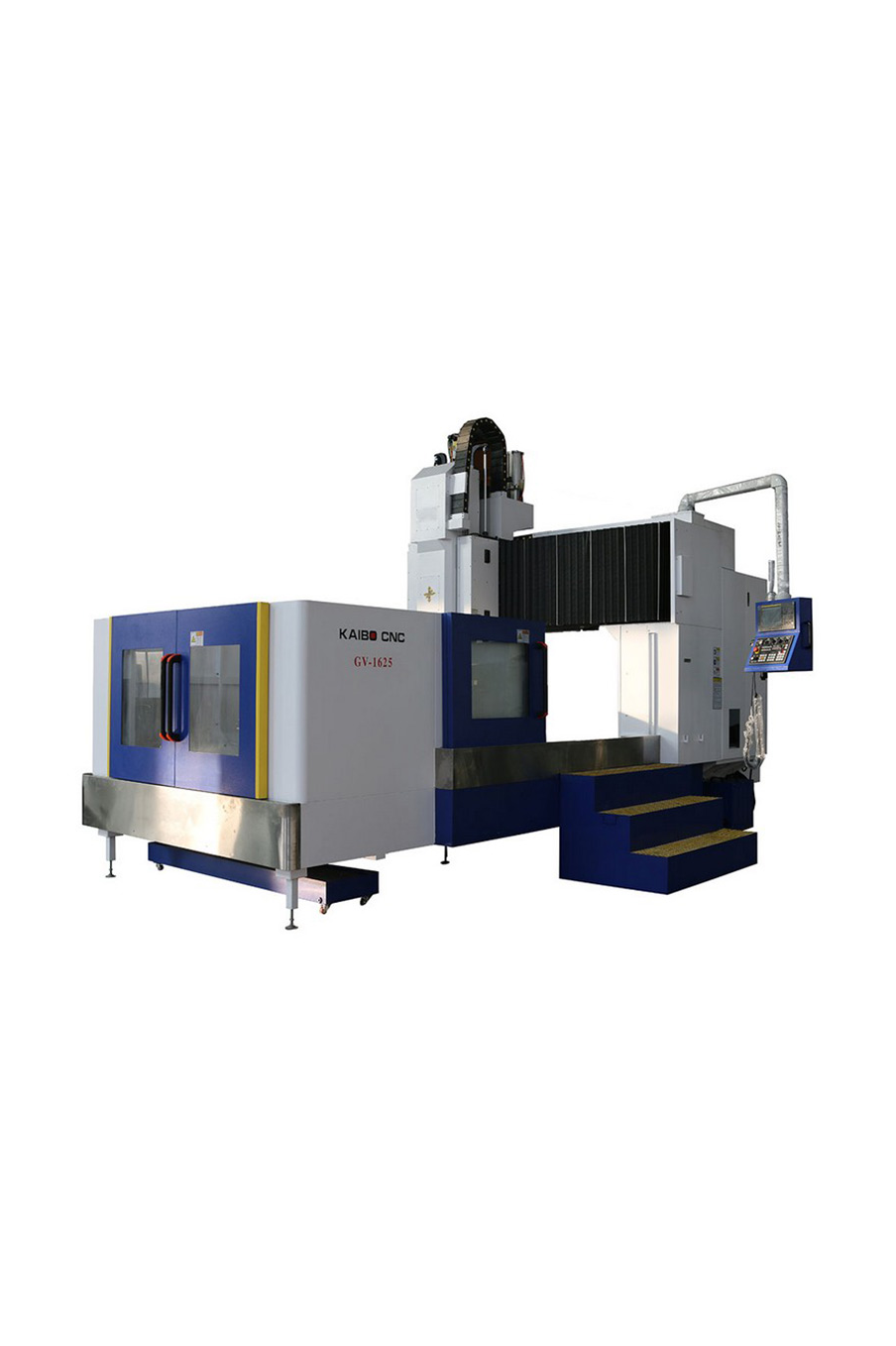

In the global market of small and medium-sized machining centers, manufacturers often face common challenges such as low processing efficiency and unstable product quality. These issues not only increase production costs but also reduce market competitiveness. To address these pain points, we are proud to introduce the DC8070A CNC milling machine, a revolutionary solution designed to transform the machining industry.

The DC8070A CNC milling machine is equipped with a high - performance spindle and advanced control system, enabling it to achieve remarkable processing speeds. Compared with traditional milling machines, it can reduce processing time by up to 30%. For example, in a project of machining a complex mechanical part, a traditional milling machine took about 5 hours, while the DC8070A completed the same task in just 3.5 hours. This significant reduction in time allows manufacturers to take on more orders and increase their overall production volume.

Precision is the key to reducing the defective product rate. The DC8070A uses high - precision ball screws and linear guides, ensuring positioning accuracy within ±0.005mm. In the production of aerospace parts where high precision is crucial, the DC8070A has demonstrated its superiority. By maintaining such high precision, the defective product rate can be reduced from the industry average of 5% to less than 1%, which directly saves a large amount of material and labor costs for manufacturers.

The machine body of the DC8070A is made of high - strength cast iron, providing excellent rigidity. This high - rigidity design allows the machine to maintain stable performance during long - term continuous operation. Even after 24 - hour continuous processing, the machine's accuracy and performance remain stable, ensuring consistent product quality. In contrast, some competing products may experience accuracy degradation after 10 - 12 hours of continuous operation.

From the customer's perspective, the DC8070A CNC milling machine brings multiple benefits. Firstly, it increases production efficiency, allowing customers to fulfill more orders in a shorter time. Secondly, the low defective product rate reduces waste and rework costs, directly saving money. Thirdly, the stable performance and high - quality products help customers enhance their brand image and gain more market share. For instance, a small - scale machining factory increased its annual revenue by 25% after using the DC8070A, mainly due to increased production volume and reduced defective products.

One of our customers, a medium - sized manufacturing company in Europe, was struggling with high production costs and low - quality products. After purchasing the DC8070A CNC milling machine, they were able to reduce their production costs by 20% within six months. The defective product rate dropped from 8% to 2%, and their product quality was highly recognized in the market. As a result, they received more large - scale orders and expanded their business.

In conclusion, the DC8070A CNC milling machine is a game - changer in the small and medium - sized machining center market. It offers high - speed processing, high precision, and high rigidity, which can significantly improve production efficiency, reduce costs, and enhance market competitiveness for customers. If you are looking for a reliable and high - performance milling machine, we strongly recommend that you consider the DC8070A.

Don't miss this opportunity to transform your machining business! Contact us now at [Contact Email] or [Contact Phone Number] to learn more about the DC8070A CNC milling machine and how it can benefit your company. Let's work together to achieve greater success!

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home