In the global market of small and medium-sized machining centers, many procurement decision-makers are constantly troubled by several common issues. The low processing efficiency often leads to long production cycles, and the unstable quality of products can cause a high rate of defective products. For instance, traditional milling machines may take up to 8 hours to complete a complex part, and the defective rate can reach 10%. These problems not only increase production costs but also reduce the competitiveness of enterprises in the market.

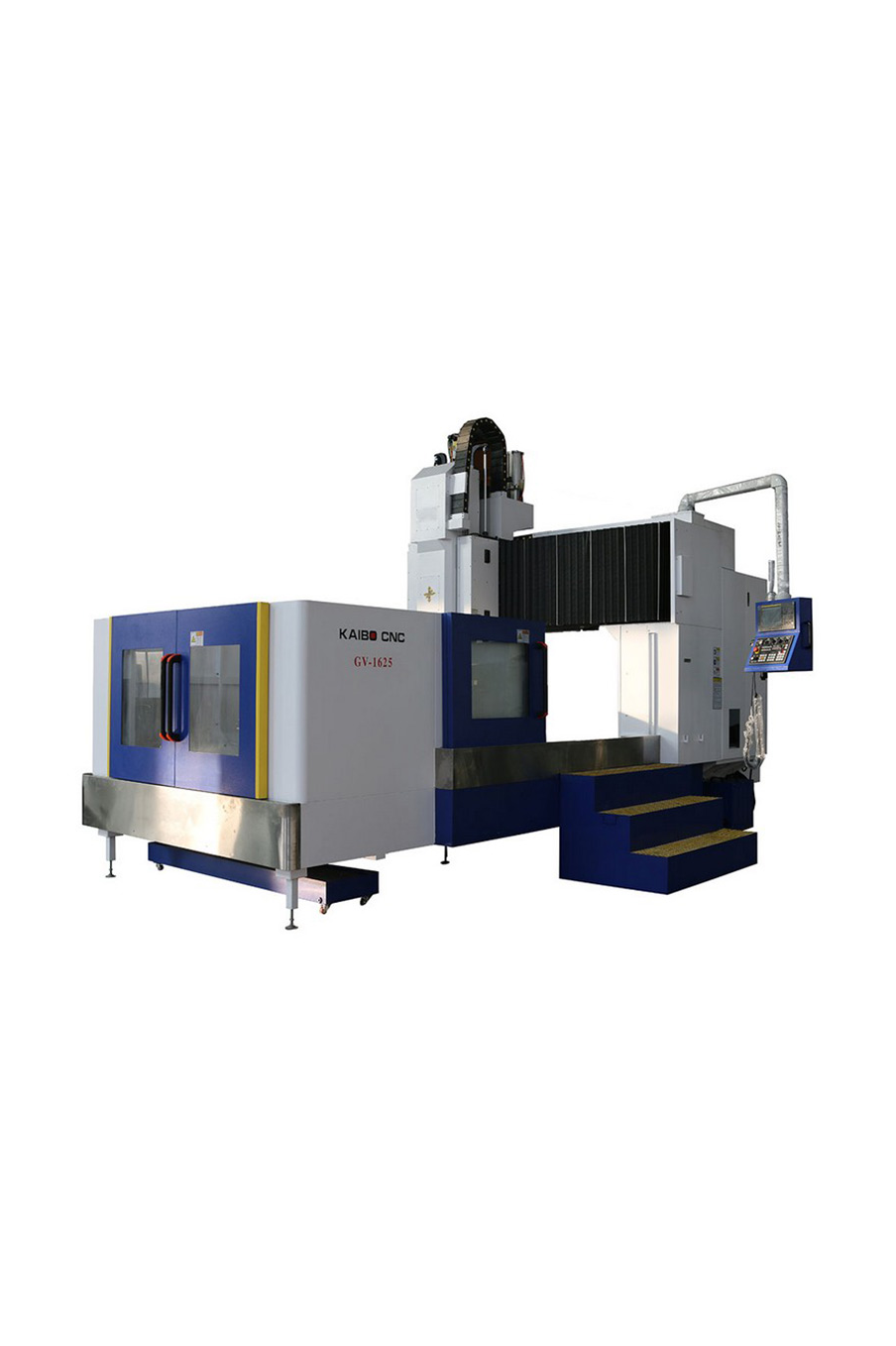

To solve these problems, we are proud to introduce the four-axis CNC milling machine DC8070A, a small and medium-sized double-column machining center. This machine is well - known for its high - speed processing, high precision, and high rigidity.

Let's first talk about high - speed processing. Compared with traditional milling machines, the DC8070A can reduce the processing time of the same complex part from 8 hours to just 3 hours, which is a significant improvement of over 60%. This means that you can increase your production volume in the same period, thereby increasing your overall output.

In terms of precision, the DC8070A has a positioning accuracy of ±0.005mm and a repeat positioning accuracy of ±0.003mm. Traditional milling machines usually have a positioning accuracy of about ±0.02mm, which is far less accurate than the DC8070A. With such high precision, you can ensure the high - quality production of your products and greatly reduce the defective rate. In fact, the defective rate can be reduced from 10% to less than 1%.

As for high rigidity, the DC8070A is designed with a double - column structure, which provides excellent stability during the machining process. It can withstand higher cutting forces, reducing the vibration and deformation of the machine during operation. This not only improves the processing quality but also extends the service life of the machine tools. Traditional milling machines may need major maintenance every 2 years, while the DC8070A only needs maintenance once every 5 years, which can save you a lot of maintenance costs.

From a customer's perspective, the DC8070A brings many benefits. Firstly, in terms of cost, as mentioned above, the reduction in processing time and maintenance costs can significantly reduce your overall production cost. Secondly, the high - quality products produced by the DC8070A can enhance your brand image in the market and increase customer satisfaction. Thirdly, with the increased production volume and high - quality products, you can gain a stronger competitive edge in the market.

For example, a manufacturing company in Germany used to produce 100 parts per day with traditional milling machines, and the defective rate was about 8%. After purchasing the DC8070A, they can produce 250 parts per day, and the defective rate is less than 1%. This has not only increased their revenue but also made them more competitive in the European market.

There are many other success stories of using the DC8070A. A Japanese precision parts manufacturer was facing intense competition in the Asian market. After introducing the DC8070A, they were able to produce high - precision parts more efficiently. Their market share in Asia has increased from 15% to 30% within one year, and their profits have also increased significantly.

The DC8070A is a game - changer in the small and medium - sized machining center market. It can help you increase production, reduce costs, and enhance your market competitiveness. If you are looking for a reliable and high - performance CNC milling machine, we strongly recommend that you consider the DC8070A. Don't miss this opportunity to transform your manufacturing business!

Contact us now to learn more about the DC8070A and get a free consultation!

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home