A well - known parts manufacturer was facing challenges in meeting the high - precision requirements of their products. They were struggling with high次品率 and long production cycles. After evaluating various options, they decided to invest in the 4 - axis CNC milling machine DC8070A with an automatic tool changer. This decision transformed their production process.

Before the adoption of DC8070A, their次品率 was around 15%. However, within six months of using this machine, the次品率 dropped to less than 3%. Production efficiency also increased by 30%, thanks to the high - speed processing capabilities of the DC8070A.

The DC8070A is equipped with a state - of - the - art control system. It can achieve a positioning accuracy of ±0.005mm. This high - precision control allows for precise movement of the cutting tool, ensuring that each part is machined to the exact specifications.

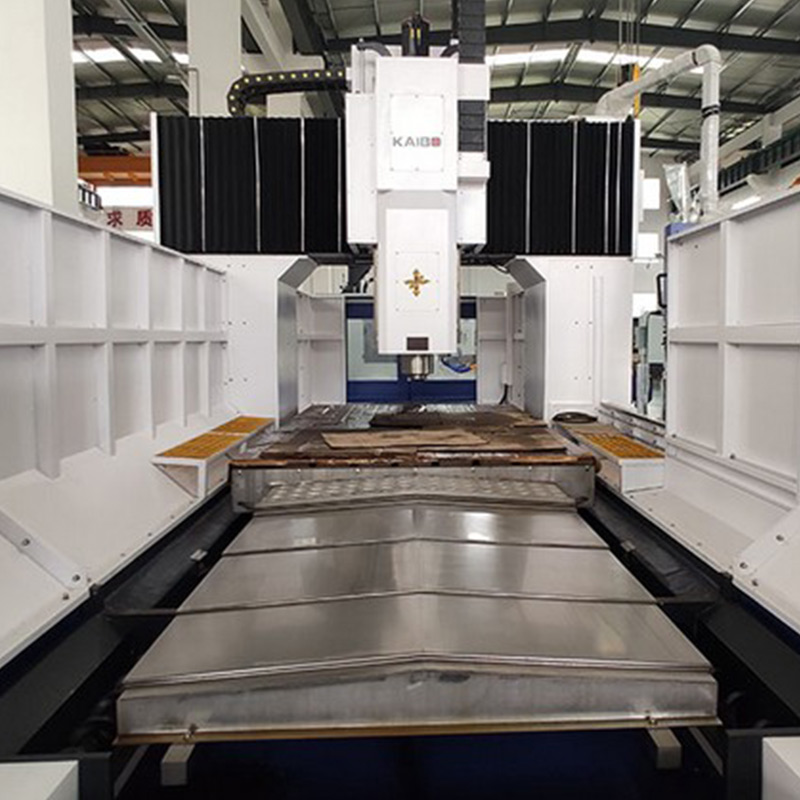

The mechanical structure of the DC8070A is designed for maximum stability. The double - column structure provides high rigidity, reducing vibration during the machining process. Tests have shown that the vibration amplitude is less than 0.01mm, which is crucial for high - precision machining.

The automatic tool changer can change tools in less than 3 seconds. Its positioning accuracy is within ±0.003mm. This fast and accurate tool change ensures continuous and efficient production, reducing downtime and improving productivity.

| Features | DC8070A | Competitor A | Competitor B |

|---|---|---|---|

| Positioning Accuracy | ±0.005mm | ±0.01mm | ±0.015mm |

| Tool Change Time | Less than 3 seconds | 5 seconds | 6 seconds |

| Vibration Amplitude | Less than 0.01mm | 0.02mm | 0.03mm |

In the automotive parts manufacturing industry, the DC8070A has been used to produce engine components with extremely high precision. The surface roughness of the machined parts can reach Ra0.8μm, which meets the strict quality requirements of the automotive industry.

In the plastic mold - making industry, the DC8070A has helped manufacturers reduce the production cycle of molds by 25%. The high - precision machining ensures that the molds have a longer service life and better quality.

In large - scale machining projects, the DC8070A's high - speed and high - precision capabilities have been fully demonstrated. It can handle large - sized workpieces with high efficiency, reducing production costs by 20%.

The DC8070A 4 - axis CNC milling machine with an automatic tool changer can significantly improve your product quality, reduce the defect rate, and enhance production efficiency. Don't miss this opportunity to take your manufacturing to the next level.

Contact Us NowThe page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home