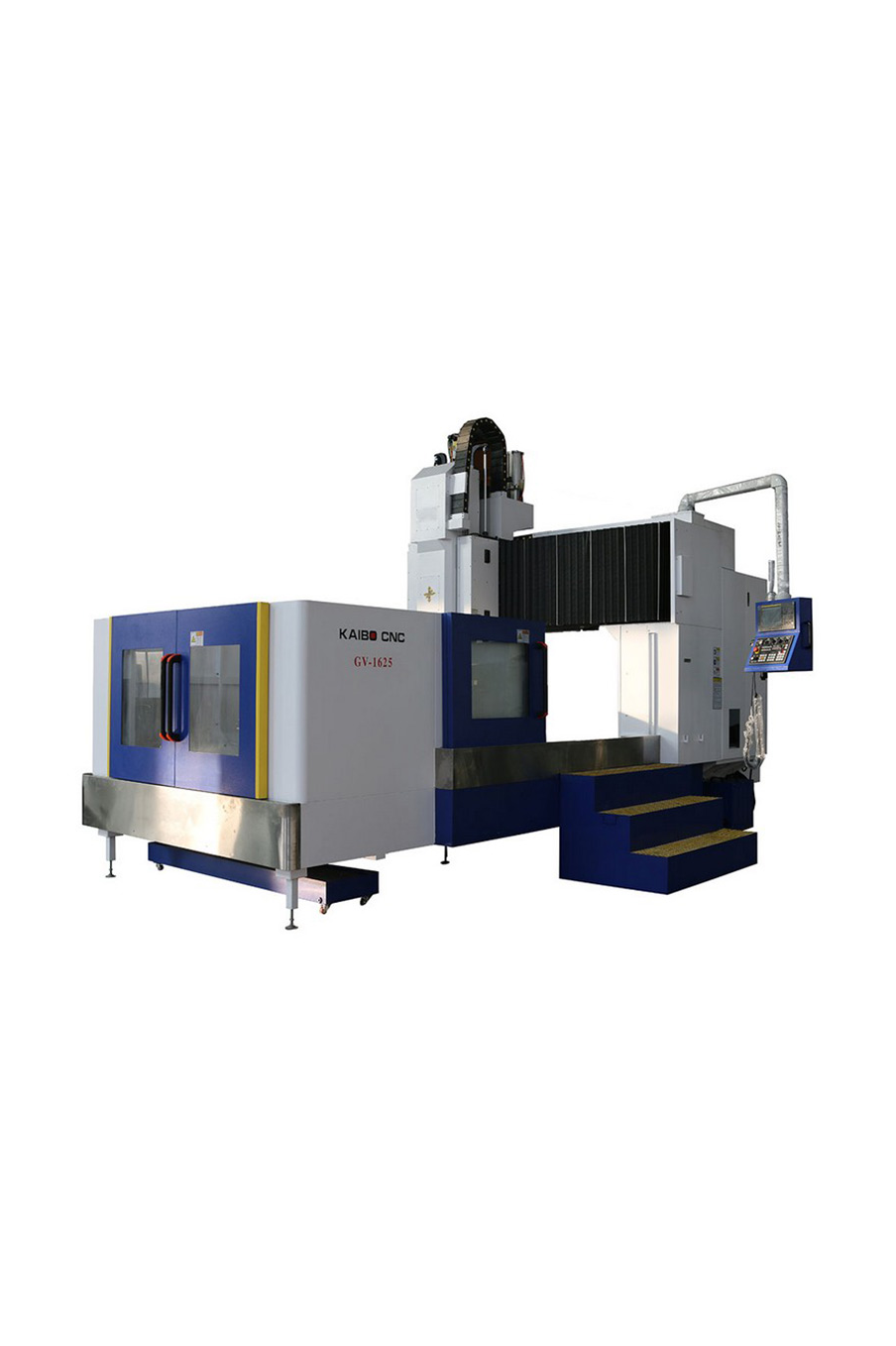

The DC2025 Gantry CNC Milling Machine is a high-performance, large-scale double-column vertical machining center specifically designed for complex and large mold manufacturing. With its advanced technology and precision engineering, this machine has become an essential tool for manufacturers around the world seeking to enhance product quality and market competitiveness.

One of the standout features of the DC2025 is its exceptional precision, which is achieved through a combination of high-quality components and advanced control systems. The machine’s spindle system, for instance, delivers a maximum speed of 8,000 RPM, ensuring efficient cutting even on the most challenging materials. Its positioning accuracy reaches up to ±0.02 mm, making it ideal for intricate mold designs that demand tight tolerances.

Compared to traditional machining centers, the DC2025 offers a 30% improvement in surface finish quality and a 25% reduction in cycle time. This performance boost is supported by real-world data from multiple customers who have integrated the machine into their production lines.

Several leading manufacturers have adopted the DC2025 to meet their growing demands for high-precision mold production. One automotive parts supplier in Germany reported a significant increase in output efficiency after replacing their old equipment with the DC2025. They were able to reduce mold production time by 20%, while also achieving a 15% improvement in part consistency.

In another case, a plastic injection molding company in China saw a dramatic improvement in product quality. By using the DC2025, they reduced defect rates by 18%, directly contributing to higher customer satisfaction and repeat business.

The DC2025 not only enhances productivity but also brings long-term value to businesses. Its robust design ensures minimal downtime and easy maintenance, reducing overall operational costs. Additionally, the machine supports a wide range of materials, including aluminum, steel, and various alloys, making it a versatile solution for diverse manufacturing needs.

| Feature | Performance |

|---|---|

| Positioning Accuracy | ±0.02 mm |

| Spindle Speed | Up to 8,000 RPM |

| Material Compatibility | Aluminum, Steel, Cast Iron, etc. |

| Surface Finish Quality | Improved by 30% |

The DC2025 Gantry CNC Milling Machine is more than just a machine—it's a strategic investment in precision, efficiency, and long-term growth. Whether you're producing large molds for automotive, aerospace, or consumer goods industries, the DC2025 provides the reliability and performance needed to stay ahead of the competition.

For global buyers looking to enhance their manufacturing capabilities, the DC2025 is a proven solution that combines cutting-edge technology with real-world results. Don't miss the opportunity to elevate your production standards and drive sustainable growth.

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home