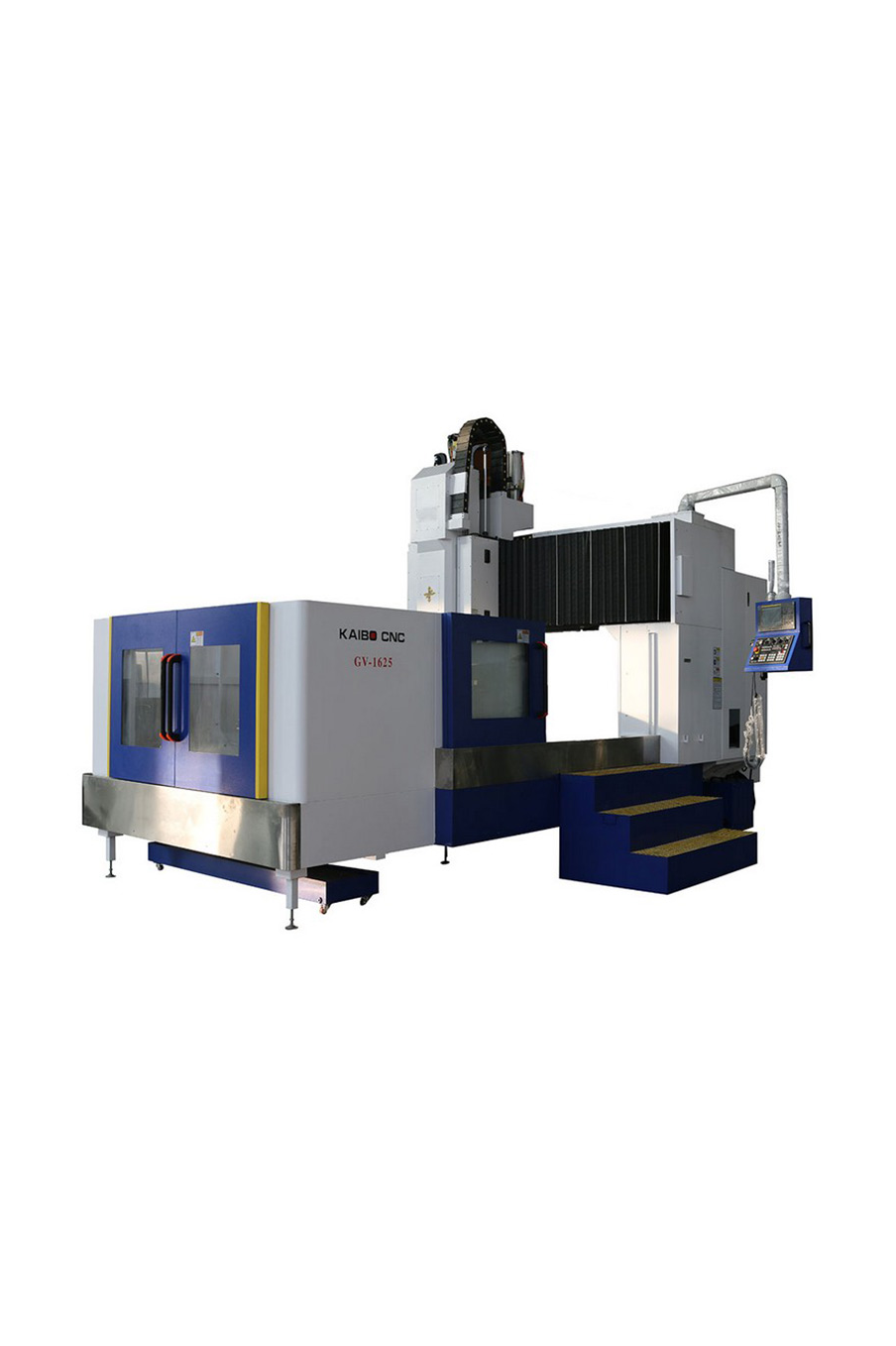

The DC2025龙门 CNC milling machine has become a key solution for high-precision processing of large molds in the global manufacturing industry. As a large double-column vertical machining center, this machine is specifically designed to meet the demanding requirements of large mold production, ensuring accurate shaping of both the external contours and internal details of molds.

With advanced technology and robust performance, the DC2025 has proven its reliability in real-world applications. Below are some detailed case studies that highlight its high-precision capabilities and the value it brings to customers.

A leading automotive parts manufacturer in Germany faced challenges with the precision of their large injection molds. The traditional machines they used could not maintain consistent accuracy across complex surfaces, resulting in quality issues and increased rework costs.

After switching to the DC2025龙门 CNC milling machine, the company reported a significant improvement in mold accuracy. The machine achieved a surface finish of 0.005 mm, which was previously unattainable with their old equipment. This enhancement reduced the need for post-processing and improved overall production efficiency by 30%.

In the aerospace sector, precision is non-negotiable. A major aerospace supplier in the United States needed to produce large molds for composite parts with extremely tight tolerances. Their previous solutions were unable to meet the required standards consistently.

By integrating the DC2025龙门 CNC milling machine into their workflow, the company achieved a dimensional accuracy of ±0.002 mm. This level of precision ensured that each component met the strict specifications set by international aviation authorities. Additionally, the machine's stability and repeatability reduced tool wear and extended machine life, contributing to long-term cost savings.

A plastic mold manufacturer in China was struggling with long lead times and inconsistent product quality. They needed a machine that could handle large mold sizes while maintaining high precision throughout the entire machining process.

After implementing the DC2025龙门 CNC milling machine, the company saw a reduction in machining time by 25% and an increase in product consistency by 40%. The machine’s ability to process multiple complex features in one setup significantly improved productivity and reduced labor costs.

| Feature | Specification |

|---|---|

| Maximum Workpiece Size | 2500 mm x 1500 mm x 800 mm |

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | 8,000 - 20,000 RPM |

The DC2025龙门 CNC milling machine not only meets but exceeds the expectations of modern mold manufacturing. Its high precision, durability, and efficiency make it an ideal choice for companies looking to enhance product quality and gain a competitive edge in the global market.

Ready to elevate your mold manufacturing capabilities? Contact us today to learn more about how the DC2025龙门 CNC milling machine can transform your production process and deliver superior results. Get in Touch Now

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home