The large mold processing industry is currently grappling with several significant challenges. Precision instability is a major headache for manufacturers. In fact, statistics show that up to 30% of large - scale mold production suffers from accuracy deviations, which can lead to rework and increased costs. Moreover, the low efficiency of traditional machining methods is another bottleneck. The average processing time for a large - sized mold can take up to 200 hours, severely limiting production capacity and responsiveness to market demands.

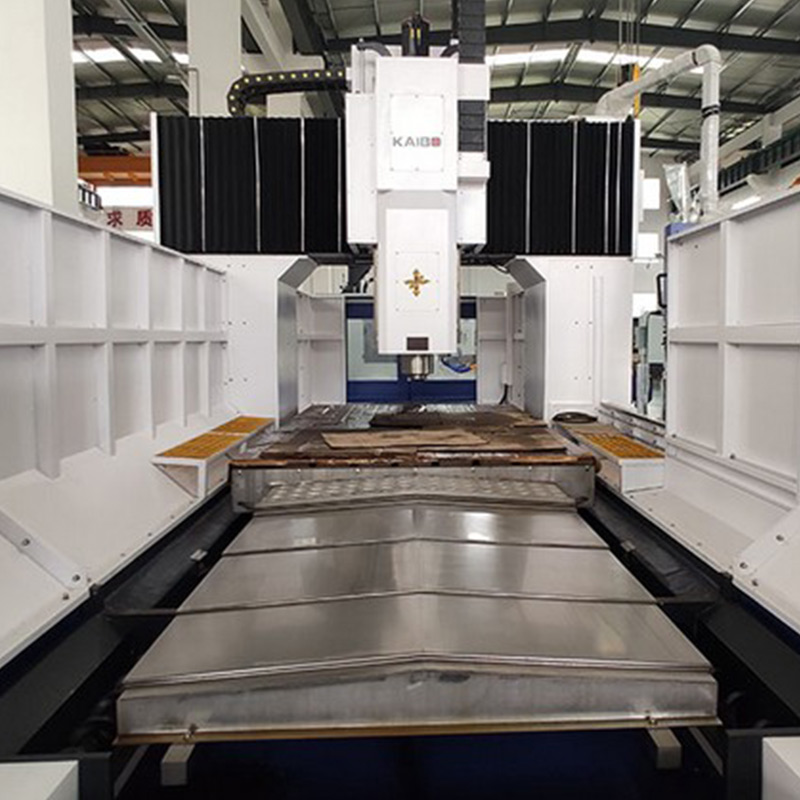

The DC2025 gantry CNC milling machine stands out with its remarkable rigidity. Rigidity is crucial in the machining process as it directly affects the stability of the cutting process. A rigid machine can maintain a stable cutting path, reducing vibrations and ensuring high - precision machining. For instance, during high - speed cutting, a rigid machine like DC2025 can achieve a surface roughness as low as Ra 0.8μm, which is far superior to ordinary machines. This high - precision machining capability can significantly improve the quality of large molds, meeting the strict requirements of high - end industries such as automotive and aerospace.

The double - column vertical structure of DC2025 is a key factor in enhancing its overall rigidity. Unlike ordinary structures, which often lack sufficient support and stability, the double - column design provides a more balanced and solid framework. The two columns act as strong pillars, effectively distributing the cutting forces. In contrast, a single - column or non - symmetrical structure may experience uneven stress distribution, leading to deformation and reduced machining accuracy. Studies have shown that the double - column vertical structure can increase the machine's overall rigidity by up to 40% compared to common structures.

In practical applications, DC2025 offers numerous advantages. Firstly, it allows for higher cutting parameters. The increased rigidity enables the machine to handle higher feed rates and cutting depths. For example, the feed rate can be increased by up to 50% compared to traditional machines, significantly reducing the machining time. Secondly, the shortened processing time translates into lower production costs. By reducing the time spent on each mold, manufacturers can save up to 25% in labor and energy costs. Additionally, the high - precision machining reduces the need for post - processing, further cutting down on costs.

One of our customers, a large - scale mold manufacturer in Europe, was facing the same challenges of low precision and efficiency. After implementing the DC2025 gantry CNC milling machine, they witnessed a remarkable transformation. The precision of their mold production improved from an accuracy deviation of ±0.05mm to ±0.01mm. The processing time for their large molds was reduced from an average of 180 hours to 100 hours. As a result, their production capacity increased by 35%, and they were able to take on more high - end orders, enhancing their market competitiveness.

In conclusion, the DC2025 gantry CNC milling machine offers a comprehensive solution to the challenges in the large mold processing industry. Its high rigidity, enabled by the double - column vertical structure, ensures high - precision and efficient machining. By increasing cutting parameters, shortening processing time, and reducing production costs, DC2025 can significantly enhance a manufacturer's production efficiency and market competitiveness. If you are looking to take your large mold processing to the next level, don't miss out on the opportunity to experience the advantages of DC2025. Click here to learn more and make a wise decision for your business!

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home