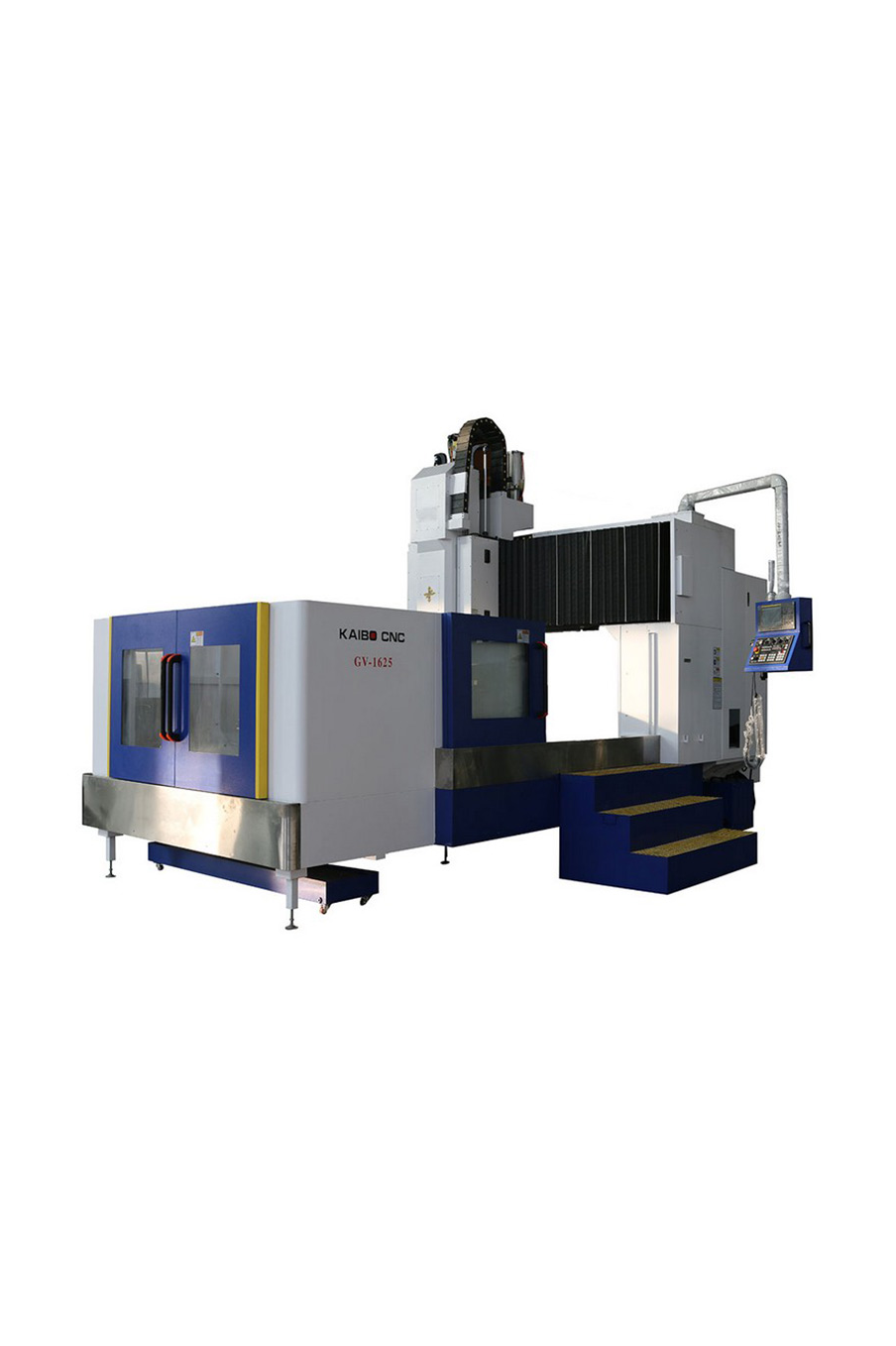

The manufacturing industry is constantly evolving, and the demand for precision and efficiency in large mold production has never been higher. As global manufacturers seek to improve productivity while maintaining high-quality standards, the need for advanced machining solutions becomes critical. Among these, the DC2025龙门 CNC Milling Machine stands out as a powerful tool that addresses the core challenges of large mold processing with unmatched rigidity, accuracy, and performance.

In the context of large mold manufacturing, machine rigidity is not just a technical feature—it's a fundamental requirement for ensuring consistent quality and reducing downtime. Traditional machining centers often struggle with vibration and deflection under heavy cutting loads, which can lead to dimensional inaccuracies and lower production rates.

The DC2025龙门 CNC Milling Machine is engineered with a robust dual-column structure that significantly enhances its rigidity. This design ensures that the machine can withstand high cutting forces without compromising stability or surface finish. According to internal testing data, the DC2025 exhibits a stiffness improvement of up to 35% compared to conventional single-column machines, making it ideal for complex and large-scale mold operations.

Several leading manufacturers have already adopted the DC2025龙门 CNC Milling Machine and reported significant improvements in both efficiency and cost control. One such case involves a major automotive parts supplier in Germany, which integrated the DC2025 into its production line for large injection molds. After implementation, the company achieved a 28% increase in production output and reduced machining time by 15% per mold.

Another example comes from a Chinese mold manufacturer that previously relied on older CNC systems. With the DC2025, they were able to cut down on rework and scrap rates by 22%, directly contributing to a 17% reduction in overall production costs. These results highlight the machine’s ability to deliver measurable economic benefits.

| Performance Metric | Before DC2025 | After DC2025 |

|---|---|---|

| Production Output (per mold) | 12 hours | 9 hours |

| Scrap Rate | 8% | 5.5% |

| Machine Downtime | 12% of total time | 6% of total time |

The DC2025龙门 CNC Milling Machine is more than just a machine—it's a strategic investment that positions manufacturers to compete globally. Its high-speed spindle, precise linear guides, and advanced control system work together to ensure optimal performance across a wide range of materials, including steel, aluminum, and composite materials commonly used in large mold applications.

For decision-makers looking to upgrade their production capabilities, the DC2025 offers a compelling combination of reliability, performance, and return on investment. By integrating this machine into their workflow, companies can meet tight deadlines, reduce operational costs, and maintain a competitive edge in the market.

Experience the power of the DC2025龙门 CNC Milling Machine and take your large mold manufacturing to the next level. Whether you're looking to increase efficiency, reduce costs, or enhance product quality, this machine is designed to meet your needs.

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home