In the ever - evolving automotive parts machining industry, the demand for high - precision equipment has reached an all - time high. As vehicles become more advanced, with features such as autonomous driving and electric powertrains, the complexity and precision requirements of automotive parts have increased significantly. This has led to a surge in the need for machines that can deliver exceptional accuracy and efficiency.

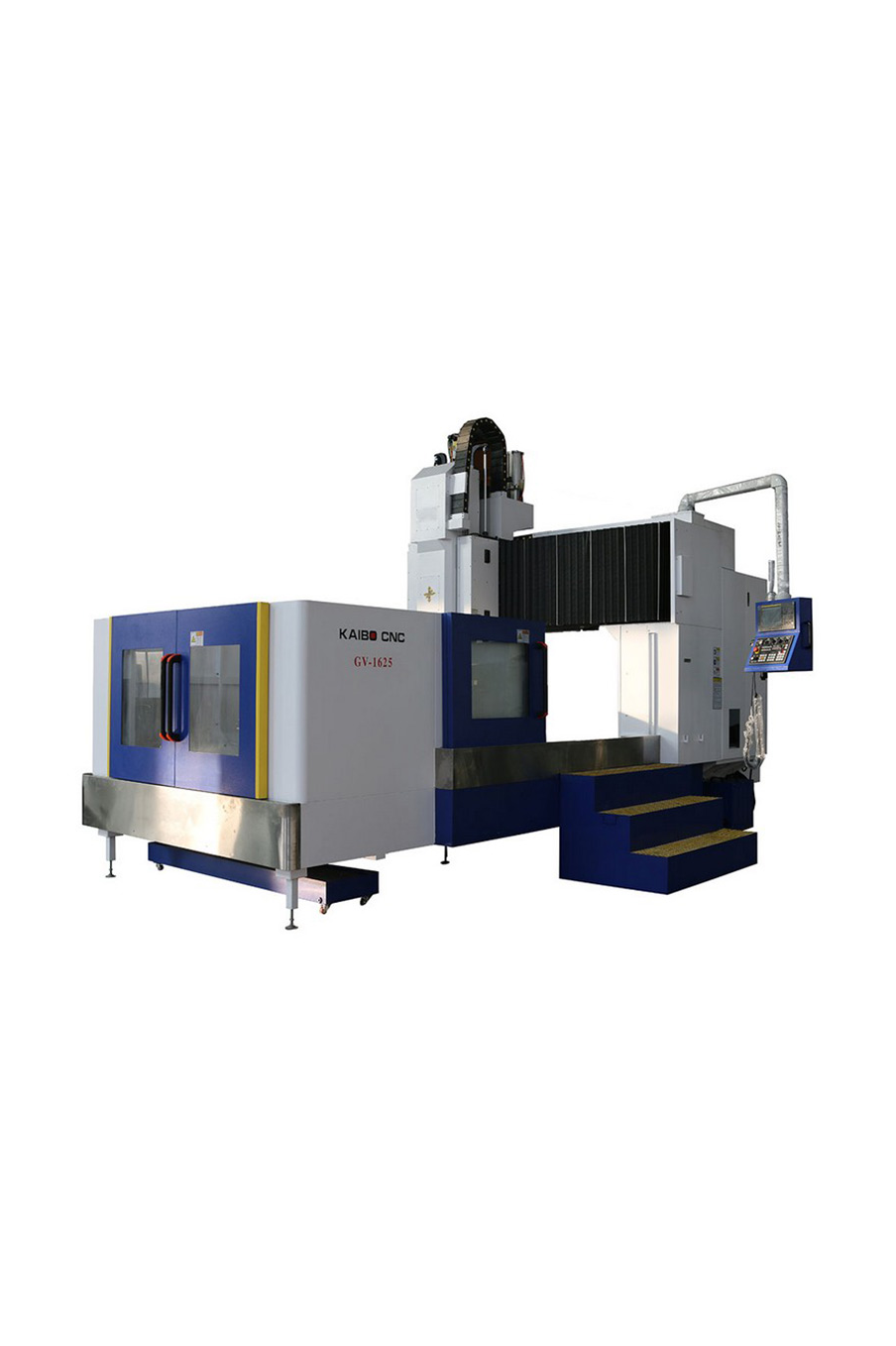

Against this backdrop, the high - precision CNC milling machine DC1520 emerges as a game - changer. It is a gantry - type device specifically designed for large - size mold processing, making it an ideal fit for the automotive parts machining sector.

The DC1520 comes with a series of special designs tailored to the unique needs of automotive parts machining. Its gantry structure provides excellent stability during the machining process, which is crucial for maintaining accuracy when dealing with large - scale parts. The machine's control system is programmed to handle complex geometries commonly found in automotive components, such as engine blocks, transmission cases, and suspension parts.

For example, it can perform multi - axis machining operations with ease, allowing for the creation of intricate shapes and contours. This adaptability makes it suitable for a wide range of automotive parts, from small, high - precision components to large structural parts.

The DC1520 is renowned for its high - precision features. It can achieve a positioning accuracy of up to ±0.005mm and a repeatability of ±0.003mm. These figures are far superior to many of its competitors in the market. This high level of precision translates directly into improved product quality.

A case in point is a leading automotive parts manufacturer that switched to the DC1520. Before using the machine, they experienced a rejection rate of about 3% due to dimensional inaccuracies. After implementing the DC1520, the rejection rate dropped to less than 0.5%, resulting in significant cost savings and improved customer satisfaction.

High rigidity is another key advantage of the DC1520. Rigidity refers to the machine's ability to resist deformation under cutting forces. The DC1520 is built with a robust frame and high - quality components, ensuring high rigidity throughout the machining process.

This high rigidity allows for higher cutting speeds and feeds, which in turn increases productivity. For instance, compared to traditional milling machines, the DC1520 can increase the machining efficiency by up to 30%. Additionally, it reduces vibration and chatter, resulting in a smoother surface finish on the machined parts.

Many customers have expressed their satisfaction with the DC1520. A European automotive parts supplier stated, "The DC1520 has revolutionized our production process. Its precision and reliability have allowed us to meet the strict quality standards of our customers in the automotive industry." Another customer from Asia mentioned that the high rigidity of the machine has significantly improved their production efficiency and reduced maintenance costs.

In conclusion, the high - precision CNC milling machine DC1520 offers unique value in the context of future automotive parts machining trends. Its special design, high - precision features, high rigidity, and positive customer feedback make it a top choice for automotive parts manufacturers worldwide.

If you are looking for a reliable and efficient solution for your automotive parts machining needs, the DC1520 is the answer. Don't miss out on the opportunity to enhance your production capabilities and improve product quality. Contact us today to learn more about the DC1520 and how it can transform your business!

The page you're looking for dose not exist.

Let's get you back home.

It will jump automatically after 5 seconds!

Go Home